©2000-

Website Design by DESERT WEB MARKETING LLC.

Have a Product You think we should be using

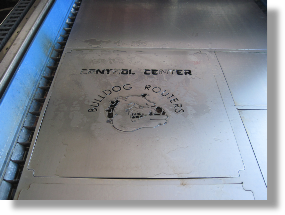

Using our CNC Plasma Machine we decided to customize the front of the main door and cut the Bull Dog Router Logo into the steel sheet that will cover the front door.

All of the sheet metal that will cover the outer surface of the control center cart was cut on the CNC Plasma Machine. We used 20 gauge cold rolled steel for the outer skin. Cutting everything on the CNC gave a a great fit and finish.

This is a view of the back side of the front door or main door for the control center. This was a late addition to the design. We formed some small pans out of stainless steel and then created a framework to hold them to the back of the front door. The stainless steel will hold led lights which will shine through the cutout in the front. Or when its off the stainless steel will provide a nice contrast.

The Cart is almost finished as this point. This is one of the last shots before we attached the ¼ inch thick steel plate top.

All of the mechanisms and and drawer slides were installed and check prior to going out for powder coating.

Its a little tough to see in this shot but the steel top has been attached and the holes were drilled in the top to allow the vacuum system connection to come up through the table top and for the wires leading down to the computer and cnc controller. We contemplated welding the top or using a bolt system to secure it so that it could be removed later. In the end we decided to weld the top to the cart and make it a one piece cart to cut down on labor time.

This cart now weights quite a bit mostly because of the ¼ plate top. We were over 300 lbs total. We had to come up with a way to hang the cart in the powder coating oven so that everything could be coated.

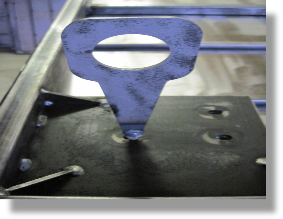

We came up with these which we plasma cut out of 1/8 steel plate and then welded to a bolt and installed it into the wheel mounts. The entire cart hung from 4 of these during the entire coating process.

Here is a view of the cart getting ready to head off to powder coating. Ready to be picked up via a fork lift using chains to the connection points.