©2000-

Website Design by DESERT WEB MARKETING LLC.

Have a Product You think we should be using

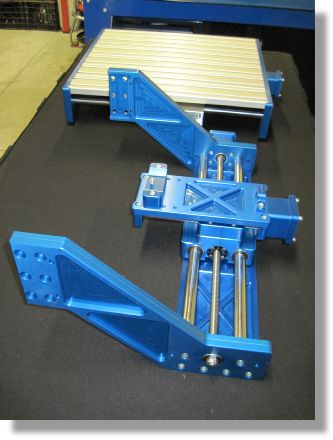

The table we chose for this project is from Precision Plasma, it is the “BullDog” model in the 15x15 size. They also have a 15x25 version of this model.

Why did we select this table? We were not looking for a huge 4x8 table to make Cabinetry on, we wanted to be able to machine aluminum parts and make some signs and other small products on. This bench top model is affordable and compact and will be great for what we are looking to do. We have been very happy with our CNC Plasma Table from Precision plasma so getting our Router table from this was a logical choice.

The size of the table does not change the basic concepts of this build. The same components and and systems are used on tables 4 or more times as large.

As far as assembly goes Precision Plasma does most of it for you. The table arrives in two pieces: The table base and the Gantry.

The only thing we had to do is bolt the gantry to the table assembly. There are 6 bolts on each side.

This table is solid. Thick Machined aluminum throughout with steel guide rods and screw shafts.

With plasma there is no contact with the object being cut so you can have a very light weight gantry to allow for speed and acceleration.

On a cnc router / mill you need strength and rigidity so that it maintains an exact position as it moves through the material. This machine is fast but only as fast as it needs to be.

When we were looking at some of the larger tables on the market they advertised extremely fast speeds of 1000 +Ipm. That’s great for some rapid moves but you are not going to be milling aluminum or routing through wood making signs at that speed.

The bit, depth of cut and material will determine the speed not how fast your steppers or servo can move.

Tools For the assembly included a 6mm Allen wrench and some blue Loctite.

Its tough to see in the picture to the right but the blue gantry arms are machined to rest on the mounting blocks. This allows the block to carry the weight of the gantry and align it. The 6 bolts on each side just lock it down tight.

With the table coming basically fully assembled you can have this ready to mount electronics in 15 minutes.

The pictures do not do this machine justice. The attention to detail, think machined aluminum components are beautiful and strong. We looked at about 6 similar machines at a recent trade show and none of them were build as well as this machine.

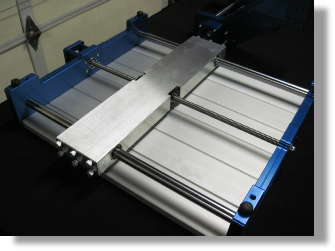

On the left is a view of the bottom of the table.