©2000-

Website Design by DESERT WEB MARKETING LLC.

Have a Product You think we should be using

The basic frame is starting to take shape. The frame dimensions are 26” Wide x 44 “ Long x 36” Tall. The bottom of the frame is 4.5” off the ground. The top frame is 1x2 rectangle tube and the uprights are 1” square tube. All .095 Wall.

This picture shows the bottom pan that was cut out of 20 Gauge Cold rolled steel sheet. The dimensions were plugged into the plasma machine and the pan was cut in one piece for a great fit.

This mounting plate was also cut on the plasma machine. It will mount to the back of the monitor. This plate will then be attached to the tilt mechanism to allow the monitor to fold.

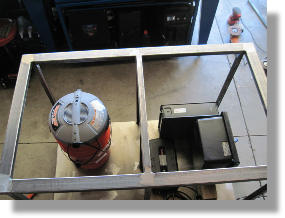

This picture shows some of the components being laid out so that the supports and mounting bars can be fabricated.

I have been welding a long time and have used lots of clamps. This auto clamp from Kreg automatically adjusts for the thickness and tension without having to adjust a screw. This was a tremendous help while tacking all of the sheet metal.

Here are the two door frames and the frames that will be turned into the shelves inside of the cabinet.

Making a little more progress. The divider between the two sections of the cart is up as well as the mounting bars for the Bladerunner control unit.

The cart will have two sides one for the computer and electronics and the other side will contain the vacuum system and the vacuum hold down unit.

Here is the vacuum hold down unit with its auxiliary vac chambers made out of ABS Pipe. The extra volume will allow for quick lock down and extra volume when needed.

Testing out the fit and function of the drawer that will hold the monitor and the keyboard. The monitor will fold using a gas strut.