©2000-

Website Design by DESERT WEB MARKETING LLC.

Have a Product You think we should be using

We came across a crowd funding project called Lcheapo Laser, and we decided to give it a try and see if we could not make it work on our CNC Router. The results were pretty good.

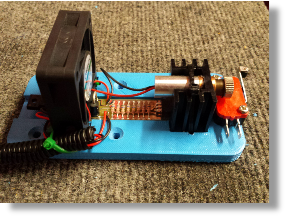

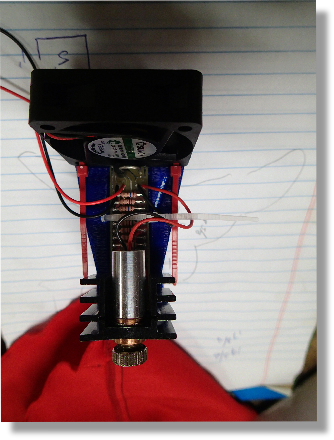

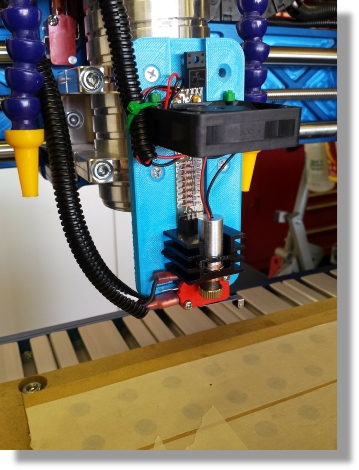

We used the 3D printer to make a quick and easy mount for the laser module. It attaches with 4 screws to the front of the Router holder and can be installed or removed in about a minute.

This laser module can cut up to ¼ Acrylic which is pretty good.

We just got this running with the new upgrades from CandCNC. We switched over to

the new Ether-

You can get more info on that conversion HERE

The Lcheapo laser came with a 3D printed mount but it was designed for working on 3D printers. It was not going to work for our application so we got on Tinkercad and made a new mount. We love having a 3D printer in our shop to make these things. We made it 8mm thick and solid fill so its very strong.

The laser fit nicely into the mount. We secured it to the mount using a few zip ties. We also added a spot at the bottom for a limit switch. This will prevent an accidental machine dive into the table and prevent damage to the laser.

The laser is powered via the 115 switched outlet on the blade runner unit. The Besttek AC/DC converter plugs into the same outlet the router normally would.

The 12v DC then goes to the laser. At this time there is no relay to control the instant on and off but that is coming in the near future.

Here is a pic of the laser mounted to the front of the Router bracket. I would have liked to mount it a little higher but the position of the screw locations and the layout of the laser prevented it, but it works well. The limit switch on the bottom prevents any damage due to a machine error.

Here are the settings I’m using: 2” focal length (bottom of laser to work)

Cut speeds tested so far: Paper -